A few steps to the optimal product

Key terms for wheels and casters

1. Select your product.

Wheels, swivel and rigid casters or press-on bands / tires can be used depending on the application.

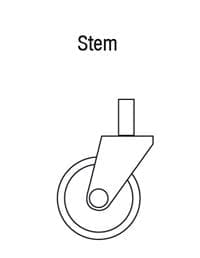

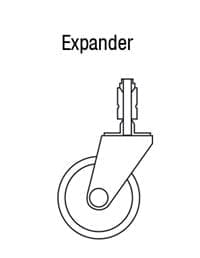

Swivel casters can rotate, while rigid casters run in a rigid direction. The casters can be attached using a top plate, bolt hole, stem, expander or plug-in stem. Information about the various fitting options is available here.

Product type

Fixing

2. Determine the required load capacity.

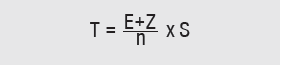

The load capacity required for a wheel or caster is calculated by dividing the dead weight of the transport equipment and its additional weight by the number of supporting wheels or casters. The result is then multiplied by a safety factor dependent on the application conditions. Find out more about dynamic load capacity.

T = required load capacity per wheel or caster

E = dead weight of the transport equipment

Z = maximum additional weight

n = number of supporting wheels or casters

S = safety factor

E = dead weight of the transport equipment

Z = maximum additional weight

n = number of supporting wheels or casters

S = safety factor

3. Starting, rolling and swivel resistance. Maneuverability.

The starting, running and swivel resistance of a wheel or caster is largely dependent on the tread, wheel bearing, wheel Ø, overall load and the condition of the surface. Resistances are explained in detail here.

The maneuverability of a transport equipment is dependent on the quantity and type of the casters which are used, as well as how they are arranged. These factors in turn affect load capacity, maneuverability, control, cornering and stability. Find out more about manoeuvrability.

The maneuverability of a transport equipment is dependent on the quantity and type of the casters which are used, as well as how they are arranged. These factors in turn affect load capacity, maneuverability, control, cornering and stability. Find out more about manoeuvrability.

Low rolling resistance

• large wheel Ø

• hard tread

• high tread elasticity

• ball bearing

• hard, smooth surface

Low swivel resistance (swivel casters)

• hard tread

• crowned tread

• large offset

• hard, smooth surface

• large wheel Ø

• hard tread

• high tread elasticity

• ball bearing

• hard, smooth surface

Low swivel resistance (swivel casters)

• hard tread

• crowned tread

• large offset

• hard, smooth surface

4. Corrosion resistance. Temperature resistance. Chemical resistance.

The service life and functionality of a wheel or caster depends to a certain extent on how well the materials used or their surface finish are capable of withstanding corrosion, temperature changes and chemical substances. Temperature and the duration of exposure are the most important factors.

Information about the chemical resistance of the different materials we use is provided in the table.

Information about the chemical resistance of the different materials we use is provided in the table.

5. Select from a wide range of tread materials.

Hardness, shape and tread material have a significant impact on the operational comfort, smooth rolling performance and starting, rolling and swivel resistance of a wheel or caster. The tread (tire) of a wheel should normally be softer than the surface. Otherwise the wheel may press into the surface and damage it. An overview of the different tread materials is available here.

| Tread material | Tread and tire hardness |

|---|---|

| Pneumatic tire, soft rubber |  |

| Elastic solid rubber, super-elastic solid rubber |  |

| Solid rubber, TPE, polyurethane 75 Shore A, silicone rubber |  |

| TPU, polyurethane 92 Shore A |  |

| Steel, cast iron, nylon, polypropylene, phenolic resin |

|

|

soft hard |

| Tread material | Operating noise |

|---|---|

| Pneumatic tire, soft rubber |  |

| Elastic solid rubber, super-elastic solid rubber |  |

| Solid rubber, TPE, polyurethane 75 Shore A, silicone rubber |  |

| TPU, polyurethane 92 Shore A |  |

| Steel, cast iron, nylon, polypropylene, phenolic resin |

|

|

loud quiet |

6. Select a wheel bearing type.

Selecting a suitable bearing will depend on the speed, load, environmental factors and the force required to move the transport equipment.

Plain bores are simple, robust and mostly insensitive

to humidity, but have the highest coefficient of

friction, and therefore a relatively high starting and

rolling resistance.

Roller bearings are robust, have a low rolling

resistance and a small radial bearing clearance.

Ball bearings have the best starting and rolling

properties, the smallest bearing clearance, a

high load capacity and are also suitable for high

speeds.

Please refer to the sections covering the different bearing types for more information.

Plain bore

Plain bore Roller bearing

Roller bearing Ball bearing

Ball bearing7. Select a suitable rig, version and options.

The suitable rig for every application and all requirements. Pressed steel rig in standard, stainless steel or heat-resistant version, welded steel heavy-duty rig with or without suspension, or elegant synthetic rig.

The functionality of wheels or casters can be enhanced by using different versions or options. Wheel and swivel head brakes to prevent swivel casters rolling and rotating, foot guard for avoiding foot injuries, electrically conductive treads for protection against electrostatic discharge and many more.

A detailed list of Blickle rig series is available here.

More information about the versions and options is available in the overview.

The functionality of wheels or casters can be enhanced by using different versions or options. Wheel and swivel head brakes to prevent swivel casters rolling and rotating, foot guard for avoiding foot injuries, electrically conductive treads for protection against electrostatic discharge and many more.

A detailed list of Blickle rig series is available here.

More information about the versions and options is available in the overview.